Defiant Pharma

Subscriber

Hello Meso,

First off, just wanted to thank everyone on here for the opportunity to be able to post up here and we look forward to being part of the commnity here for years to come, God willing.

We are Defiant Labs Pharmaceuticals, a veteran US domestic source with over 10+ years of experience. We've been in the community since 2011 with the same name since the beginning, so you’re not going to get a BS story that we’ve been around for over a decade with no proof to back it up. Over the years we’ve had an impeccable reputation on numerous boards and I think you’d be hard pressed to find any bad things said about us. We take great pride in what we do, and I think that will show in all aspects of our operation, from manufacturing, presentation, communication, transparency, customer service, shipping, op-sec, and attention to detail.

I personally compound every injectable and press every tablet in our line up. I’m a perfectionist and OCD as hell, so I trust no one but myself in the manufacturing process. It’s always been that way and always will be, because if anything is not right, I have no one to blame but myself. I try and compound all injectables and press all tablets as close to pharmaceutical standards as I can without actually being in a certified clean room.

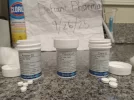

All of our injectables are made with BA/BB, GSO, and no other solvents at all. Tablets are made with just MCC(Microcrystalline Cellulose) and MS(Magnesium Stearate) as lubricant, which make for a nice clean perfectly pressed tablet. We actually press tablets for some other well known labs out there which I can’t name for obvious reasons.

STERILIZATON:

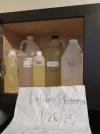

We work in as sterile of an environment as we can without actually being able to compound in a certified clean room. We wash all of our vials and stoppers with Alconox detergent, then they are rinsed with distilled water to ensure particulate elimination before putting them into an autoclave(filled with distilled water) to ensure proper sterilization and depyrogenation. Vials are then dried via dry heat in the oven at 400F for an hour to even further ensure sterilization and depyrogenation. Might be a little overkill but just they way we've always done things. Stoppers are also dried via dry heat at a lower temp. Beakers, media bottles, bottle top dispensers and any other supplies used during the manufacturing process are also sterilized via autoclave to ensure the removal of any existing endotoxins/exotoxins before we begin the manufacturing process. Work station(s) are sterilized with a bleach mixture and 91% IA prior to beginning any work. We also wear the proper attire and use sterile gloves, masks, etc. during the entire preparation and compounding process. Glassware is also cleaned with Alconox lab detergent.

COMPOUNDING:

Raw powder, BA and BB are all added together in the beaker and allowed to sit overnight to ensure the solvents do their job before we add any heat and oil to the mixture. We like to use the least amount of heat possible when brewing any of our oils. Our mixture and oil are then heated to approx the same temp before combining and mixed with a hotplate/magnetic stirrer.

We then filter our oils via peristaltic pump with whatman 36AS .2um capsule filters straight into sterilized glass media bottles(via closed system.) They are then dispensed into sterilized 10ml vials using an adjustable labmax bottle top dispenser to ensure accurate fill level for each vial(11mL). Stoppers are then inserted, then vials are capped, crimped, and labeled. All of this is done inside of our vertical laminar flow hood, except the labeling and filtration.

Like I mentioned in a previous post, we also run a high end BlueAir hepa filter in our closed off clean room for apprx 30-45min on high to ensure as many particulates as possible are removed from the air. Then the clean room is left to calm down for another 30-45min before we begin any of the steps listed above.

TABLETS:

I press my own tablets with a ZP-5B rotary press. I use only MCC(microcrystalline cellulose) as filler and MS(Magnesium Stearate ) as lubricant along with the active ingredient of course. I first sieve the raw active compound to ensure proper mixing with the MCC and MS. And for compounds that are crystallized like anavar, proviron, etc we mortar and pestle those before running them through the sieve. We then combine the active compound and MCC in our V-mixer, mix for 10-15 minutes, then add MS and mix for another 10-15 minutes. This ensures a nice homogeneous mixture, without over-mixing. Our lower MG tabs are pressed in 6mm and tabs that are 50mg+ along with Cialis(because its a bitch to press) are pressed in 9mm tabs with a score on one side. The 6mm tabs do not have a score. You will be able to see in the pics provided below.

OPSEC:

We try our best not to have any weak spots in our operation and we definitely do not slack when it comes to this. VPN, no routers or internet connections that are connected to anyone, VM's(virtual machines) or WHONIX, encrypted harddrives, etc. Shipping is done anonymously without getting into too much detail. We've been doing this 10+ yrs for a reason, we take this part of the operation very serious. Still do not use phones to access anything to do with this operation. So, the only thing with emails is sometimes it takes us a day to get back to people because I keep my laptop/internet dongle at a dedicated spot enclosed in a faraday bag. I do not keep it at home. PGP encryption is encouraged if you know how to use it. Easiest way is through Thunderbird. You can use Thunderbird with Protonmail via Proton Bridge if you have a paid account. I can walk anyone through how to set it up if needed. Just LMK.

As for shipping, we don't slack on this either. There’s a reason we’ve been around for as long as we have without any issues. T/A is 3-7 days after payment is made. It’s usually on the lower end but, we can’t control how USPS handles packages, and as most of you know sometimes USPS does some crazy re-routing and unfortunately that is out of our control. But, we try our best to get your packages to you as quick and safely as possible. Safety is our number one priority.

TESTING:

All raws are tested before compounding and we also do some finished oil testing as well. More than likely we will start doing finished oil testing on every compound from here on out. Tablets are also sent in for variance testing with Jano.

We offer $100 credit for bloodwork and $200 credit for Jano testing.

CONTACT INFO:

DefiantPharma@protonmail.com

or

dlplabs@tutanota.com

Please use the corresponding email provider for whichever provider you use. So, if you have proton email my proton addy, if you have tutanota please email the tutanota addy.

First off, just wanted to thank everyone on here for the opportunity to be able to post up here and we look forward to being part of the commnity here for years to come, God willing.

We are Defiant Labs Pharmaceuticals, a veteran US domestic source with over 10+ years of experience. We've been in the community since 2011 with the same name since the beginning, so you’re not going to get a BS story that we’ve been around for over a decade with no proof to back it up. Over the years we’ve had an impeccable reputation on numerous boards and I think you’d be hard pressed to find any bad things said about us. We take great pride in what we do, and I think that will show in all aspects of our operation, from manufacturing, presentation, communication, transparency, customer service, shipping, op-sec, and attention to detail.

I personally compound every injectable and press every tablet in our line up. I’m a perfectionist and OCD as hell, so I trust no one but myself in the manufacturing process. It’s always been that way and always will be, because if anything is not right, I have no one to blame but myself. I try and compound all injectables and press all tablets as close to pharmaceutical standards as I can without actually being in a certified clean room.

All of our injectables are made with BA/BB, GSO, and no other solvents at all. Tablets are made with just MCC(Microcrystalline Cellulose) and MS(Magnesium Stearate) as lubricant, which make for a nice clean perfectly pressed tablet. We actually press tablets for some other well known labs out there which I can’t name for obvious reasons.

STERILIZATON:

We work in as sterile of an environment as we can without actually being able to compound in a certified clean room. We wash all of our vials and stoppers with Alconox detergent, then they are rinsed with distilled water to ensure particulate elimination before putting them into an autoclave(filled with distilled water) to ensure proper sterilization and depyrogenation. Vials are then dried via dry heat in the oven at 400F for an hour to even further ensure sterilization and depyrogenation. Might be a little overkill but just they way we've always done things. Stoppers are also dried via dry heat at a lower temp. Beakers, media bottles, bottle top dispensers and any other supplies used during the manufacturing process are also sterilized via autoclave to ensure the removal of any existing endotoxins/exotoxins before we begin the manufacturing process. Work station(s) are sterilized with a bleach mixture and 91% IA prior to beginning any work. We also wear the proper attire and use sterile gloves, masks, etc. during the entire preparation and compounding process. Glassware is also cleaned with Alconox lab detergent.

COMPOUNDING:

Raw powder, BA and BB are all added together in the beaker and allowed to sit overnight to ensure the solvents do their job before we add any heat and oil to the mixture. We like to use the least amount of heat possible when brewing any of our oils. Our mixture and oil are then heated to approx the same temp before combining and mixed with a hotplate/magnetic stirrer.

We then filter our oils via peristaltic pump with whatman 36AS .2um capsule filters straight into sterilized glass media bottles(via closed system.) They are then dispensed into sterilized 10ml vials using an adjustable labmax bottle top dispenser to ensure accurate fill level for each vial(11mL). Stoppers are then inserted, then vials are capped, crimped, and labeled. All of this is done inside of our vertical laminar flow hood, except the labeling and filtration.

Like I mentioned in a previous post, we also run a high end BlueAir hepa filter in our closed off clean room for apprx 30-45min on high to ensure as many particulates as possible are removed from the air. Then the clean room is left to calm down for another 30-45min before we begin any of the steps listed above.

TABLETS:

I press my own tablets with a ZP-5B rotary press. I use only MCC(microcrystalline cellulose) as filler and MS(Magnesium Stearate ) as lubricant along with the active ingredient of course. I first sieve the raw active compound to ensure proper mixing with the MCC and MS. And for compounds that are crystallized like anavar, proviron, etc we mortar and pestle those before running them through the sieve. We then combine the active compound and MCC in our V-mixer, mix for 10-15 minutes, then add MS and mix for another 10-15 minutes. This ensures a nice homogeneous mixture, without over-mixing. Our lower MG tabs are pressed in 6mm and tabs that are 50mg+ along with Cialis(because its a bitch to press) are pressed in 9mm tabs with a score on one side. The 6mm tabs do not have a score. You will be able to see in the pics provided below.

OPSEC:

We try our best not to have any weak spots in our operation and we definitely do not slack when it comes to this. VPN, no routers or internet connections that are connected to anyone, VM's(virtual machines) or WHONIX, encrypted harddrives, etc. Shipping is done anonymously without getting into too much detail. We've been doing this 10+ yrs for a reason, we take this part of the operation very serious. Still do not use phones to access anything to do with this operation. So, the only thing with emails is sometimes it takes us a day to get back to people because I keep my laptop/internet dongle at a dedicated spot enclosed in a faraday bag. I do not keep it at home. PGP encryption is encouraged if you know how to use it. Easiest way is through Thunderbird. You can use Thunderbird with Protonmail via Proton Bridge if you have a paid account. I can walk anyone through how to set it up if needed. Just LMK.

As for shipping, we don't slack on this either. There’s a reason we’ve been around for as long as we have without any issues. T/A is 3-7 days after payment is made. It’s usually on the lower end but, we can’t control how USPS handles packages, and as most of you know sometimes USPS does some crazy re-routing and unfortunately that is out of our control. But, we try our best to get your packages to you as quick and safely as possible. Safety is our number one priority.

TESTING:

All raws are tested before compounding and we also do some finished oil testing as well. More than likely we will start doing finished oil testing on every compound from here on out. Tablets are also sent in for variance testing with Jano.

We offer $100 credit for bloodwork and $200 credit for Jano testing.

CONTACT INFO:

DefiantPharma@protonmail.com

or

dlplabs@tutanota.com

Please use the corresponding email provider for whichever provider you use. So, if you have proton email my proton addy, if you have tutanota please email the tutanota addy.

Attachments

-

20250926_130337.webp811.9 KB · Views: 989

20250926_130337.webp811.9 KB · Views: 989 -

20250926_130543.webp908.3 KB · Views: 819

20250926_130543.webp908.3 KB · Views: 819 -

20250926_130603.webp1 MB · Views: 811

20250926_130603.webp1 MB · Views: 811 -

20250926_130646.webp702.4 KB · Views: 801

20250926_130646.webp702.4 KB · Views: 801 -

20250926_130723.webp809.4 KB · Views: 774

20250926_130723.webp809.4 KB · Views: 774 -

20250926_131612.webp417.5 KB · Views: 728

20250926_131612.webp417.5 KB · Views: 728 -

20250926_131707.webp804.1 KB · Views: 724

20250926_131707.webp804.1 KB · Views: 724 -

20250926_133109.webp1.2 MB · Views: 714

20250926_133109.webp1.2 MB · Views: 714 -

20250926_133212.webp1 MB · Views: 719

20250926_133212.webp1 MB · Views: 719 -

20250926_133516.webp780 KB · Views: 745

20250926_133516.webp780 KB · Views: 745