TheLobster

Subscriber

Lobster mentioned that the batch available for EU domestic is the one that was produced when the vacuum-seal machinery was still working correctly. What you are describing is consistent with the ~2000 Pa low-vacuum that he stated as the capability of the machinery when not broken.

Arguably, the stronger vacuums present in most peptide vials from China would be preferable, since the latter contain even less air particles and humidity. Might be an argument for Lobster to upgrade his machinery instead of repairing the existing one.

EU domestic manufacturing and international manufacturing are different. I have one set up in Turkiye and another in the EU, so this means I have two machines.The machine does not apply top pressure with 5-10 Pa. Instead, the machine applies top pressure with around 2000-3000 Pa

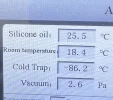

You cannot dry peptides with 2,000 Pa. The machine MUST go down to 10 Pa or lower

The first drying step requires a temperature range of -45°C to 20°C with 10 Pa

To reach 25°C, around 1-2 Pa is needed for approximately 8-10 hours

If the machine doesn’t go to these levels, you cannot properly dry peptides

I don’t need to change the machine. As I mentioned earlier, the top pressure doesn’t work with 10 Pa or lower. The top pressure only works with 2,000 Pa or higher. This is the issue.

For the EU batch, the vials are sealed with 2 Pa or lower no doubt

Whether it’s with or without vacuum, both take the same amount of time,work and the vacuum doesn’t cost me extra money. I don’t take shortcuts. Let’s be clear about this

Thank you