I need some feedback about testing for the presence of polystyrene in

US DOM vendor's oils.

Most bottletop filters are made out of / contain polystyrene one form or another. Polystyrene does not work well with neither MCT, BB or BA. It causes leeching etc.

30 minutes at 50 C

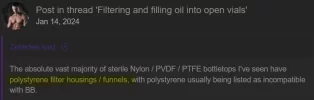

If you search around the forum, you can see people commenting about bottletop systems leeching/cracking etc. This is just one post, there's quite a few.

Think you’ve misunderstood what I was referring to mate - I should have been clearer. I was referring to the bottletop reservoir that holds the liquid before filtering & the housing around the actual filter material itself being almost always being polystyrene.

Yeah I understood what you were pointing out that's why I said replacing the receiver flask with a glass one is the best option. The holding/filtering flask can't be replaced but one can minimize contact by adding slowly and not all at once. But as

@nightprowler7 pointed out after a certain amount of bb it leaches. An...

The absolute vast majority of sterile Nylon / PVDF / PTFE bottletops I’ve seen have polystyrene filter housings / funnels, with polystyrene usually being listed as incompatible with BB.

Have any of you guys ever personally experienced problems from BB with such housings / funnels?

With high bb, over 25% I had leeching. Yes. With a 22% brew, no leeching

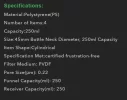

Jano seems to be able to test for it ($170 a sample) and i reckon we should test using

higher concentration gear as the leeching occurs faster during such cases.

Is there any point in going ahead with this testing?

(1) Is the assumption that US DOM vendors use a better filtration setup?

(2) Nobody has been harmed from this that we know off, gear still works?

Good to go? Nothing to test?

Anything else i missed?

It would be good if we can have some brewers chime in, especially those who use bottletop setups.