Honestly I'm confused why the mini spikes aren't readily available here. Or why the TRT clinic I started with mentioned neither of these things...I wish we had those in Europe fuck, we only have that one but with blunt needle....I don't understand why, so frustrating

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

Guest viewing limit reached

- You have reached the maximum number of guest views allowed

- Please register below to remove this limitation

- Already a member? Click here to login

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

10ml or 20ml or 30ml vials

- Thread starter Sampei

- Start date

That thing is fucking amazingI use one spike for the life of the vial.

You attach the luer lock syringe, draw, then disconnect the syringe, leaving the spike in the vial and attach needle. An added benefit is that it prevents using a separate needle to draw, or dulling the needle if using the same to draw and inject.

The model I use has a valve that closes when the syringe is removed, so nothing leaks from the vial being held upside down.

There's a vent that allows air into the vial as you draw, equalizing pressure preventing vacuum from forming.

Liquid flows through a 5 micron particle filter, vent air flows through a 2 micron air filter.

There's a cap that covers the luer connector when not in use.

View attachment 293864

View attachment 293869

View attachment 293867

View attachment 293866

Liter O' Test

Member

Ateam2023

Member

IMHO, i think ALL UGL oils should be refiltered into a sterile vial, i understand most people do not want or think they shouldn't have to , but at the end of the day , wouldn't that "extra precaution" not only ease your mind, but also prevent issues such as "PIP ,Abcesses" etc,,,,, And that goes for peptides/hgh , but atmittedlly i have yet to start that phase,,,,YET,,

This is ok for filter particles of stoppers or other stuff not to make something unsterile, sterile.what about "blunt" filtered syringes. for amps? says they are 5 microns, this would work for 1ml at a time?

View attachment 307139

Ghoul

Member

I've shifted my ideal somewhat for oils. .22um into a vial FDA certified free of particulates, then a vented spike to prevent coring. Filtered would be preferable, but I think an unfiltered spike would be acceptable.

For peptides, personally, for me I'm shifting to per dose filtration. After reconstitution, pull the entire vial into a 3ml syringe. Attach 13 or 25mm filter, attach needle, each dose is backfilled into an insulin syringe as needed. I store the 3ml syringe/filter/needle setup in a container in the fridge.

I've ordered syringes more compatible with storing peptides, ie, free of silicon.

Bit of a learning curve (ie, backfilling from a needle vs the open end of the filter is much easier), but happy with the results so far.

For peptides, personally, for me I'm shifting to per dose filtration. After reconstitution, pull the entire vial into a 3ml syringe. Attach 13 or 25mm filter, attach needle, each dose is backfilled into an insulin syringe as needed. I store the 3ml syringe/filter/needle setup in a container in the fridge.

I've ordered syringes more compatible with storing peptides, ie, free of silicon.

Bit of a learning curve (ie, backfilling from a needle vs the open end of the filter is much easier), but happy with the results so far.

Ateam2023

Member

what size needle is that?I've shifted my ideal somewhat for oils. .22um into a vial FDA certified free of particulates, then a vented spike to prevent coring. Filtered would be preferable, but I think an unfiltered spike would be acceptable.

For peptides, personally, for me I'm shifting to per dose filtration. After reconstitution, pull the entire vial into a 3ml syringe. Attach 13 or 25mm filter, attach needle, each dose is backfilled into an insulin syringe as needed. I store the 3ml syringe/filter/needle setup in a container in the fridge.

I've ordered syringes more compatible with storing peptides, ie, free of silicon.

Bit of a learning curve (ie, backfilling from a needle vs the open end of the filter is much easier), but happy with the results so far.

View attachment 307144

Ghoul

Member

what size needle is that?

27g 1/2", just what I happened to have on hand.

1/2" is perfect, but I'm going to get a larger gauge. 27g adds some resistance, and more importantly, if I apply too much pressure to the syringe, it creates foaming, which is definately unwanted. Minimizing air/liquid interface of the peptide solution is recognized as reducing degradation.

If anyone's wondering why "per dose" filtration rather than the entire vial at once, it's for two reasons.

1. Aggregate formation takes time. So the longer the time between when you filtered and when you inject, the more aggregates will reform.

2. There's an "equilibrium" factor with aggregates. As soon as aggregates are removed from a peptide solution, more will begin to form until equilibrium is reached. In other words, all other things being equal, the lack of aggregates acts to accelerate the formation of new aggregates. So in a sense, better to keep the solution unfiltered until the last minute, only filtering the quantity needed.

Still, all that said, filtering an entire vial once is better than not filtering at all. Whatever you find practical for you and are willing to do. Don't let the "perfect" be the enemy of "good".

bigMoJo

Member

Juat as a "Public Service Announcement" for Re-filtering:

AAS Oils:

1. For completely re-filtering oils, ideally: Sterile .22um PTFE 33mm hydrophilic syringe filter. 33mm will allow filtering up to 50ml. However, good luck finding any under $200 for 100 qty. in the US. They're not sold at anything less than that at the moment. 25mm will allow filtering up to 20ml, still difficult to find, but available. 13mm, up to 10ml, a little easier to find.

2. Re-filter into sterile vial. @Ghoul and @Sampei have posted some that fit the right specs. Thank you to you both, by the way.

PEPTIDES:

1. For completely refiltering peptides, ideally: Sterile .22um PES 13mm hydrophillic syringe filter. I have found that 13mm will filter 10ml no problem, but possibly much more. Finding PES filters is not a problem, and they come in 25mm size as well.

2. Again, re-filter into sterile vial.

NOTE: pay attention to "hydrophilic" versus "hydrophobic," as the latter is not for "aqueous" solutions.

AAS Oils:

1. For completely re-filtering oils, ideally: Sterile .22um PTFE 33mm hydrophilic syringe filter. 33mm will allow filtering up to 50ml. However, good luck finding any under $200 for 100 qty. in the US. They're not sold at anything less than that at the moment. 25mm will allow filtering up to 20ml, still difficult to find, but available. 13mm, up to 10ml, a little easier to find.

2. Re-filter into sterile vial. @Ghoul and @Sampei have posted some that fit the right specs. Thank you to you both, by the way.

PEPTIDES:

1. For completely refiltering peptides, ideally: Sterile .22um PES 13mm hydrophillic syringe filter. I have found that 13mm will filter 10ml no problem, but possibly much more. Finding PES filters is not a problem, and they come in 25mm size as well.

2. Again, re-filter into sterile vial.

NOTE: pay attention to "hydrophilic" versus "hydrophobic," as the latter is not for "aqueous" solutions.

Last edited:

Ateam2023

Member

I prefer hydrophobic for oils. Just because in my mind If any small water condensation has formed during brewing it will be filtered out. Of course this is all in my mind and both works perfectly fine.i have also used a sterile .22um ptfe hydrophobic syringe filter to filter oils , i could comfortably push 30-40 ml through each filter with no problems, is there that big a difference between hydrophobic and hydrophilic when filtering oils? Or am i mistaken?View attachment 307216

With hydrophobic you can't filter water so in case you are doing your own bac water and you don't have access to sterile water you need hydrophilic filters for that. Just a reminder.

No bigger than 13mm, as the bigger it gets the more retained solution into the filter even after blowing air through the filter. 4mm works ok too if you are just filtering 3-4ml.Juat as a "Public Service Announcement" for Re-filtering:

AAS Oils:

1. For completely re-filtering oils, ideally: Sterile .22um PTFE 33mm hydrophilic syringe filter. 33mm will allow filtering up to 50ml. However, good luck finding any under $200 for 100 qty. in the US. They're not sold at anything less than that at the moment. 25mm will allow filtering up to 20ml, still difficult to find, but available. 13mm, up to 10ml, a little easier to find.

2. Re-filter into sterile vial. @Ghoul and @Sampei have posted some that fit the right specs. Thank you to you both, by the way.

PEPTIDES:

1. For completely refiltering peptides, ideally: Sterile .22um PES 13mm hydrophillic syringe filter. I have found that 13mm will filter 10ml no problem, but possibly much more. Finding PES filters is not a problem, and they come in 25mm size as well.

2. Again, re-filter into sterile vial.

NOTE: pay attention to "hydrophilic" versus "hydrophobic," as the latter is not for "aqueous" solutions.

Ateam2023

Member

I can use a sterile PES syringe filter to filter distilled water to make bac water can't i ?I prefer hydrophobic for oils. Just because in my mind If any small water condensation has formed during brewing it will be filtered out. Of course this is all in my mind and both works perfectly fine.

With hydrophobic you can't filter water so in case you are doing your own bac water and you don't have access to sterile water you need hydrophilic filters for that. Just a reminder.

Ghoul

Member

can i use a PES syringe filter to filter distilled water to make bac water?

No. .22um can't remove endotoxin. It doesn't even remove all bacteria.

Ghoul

Member

im mistaken , its a PTFE hydrophilic filter i use for sterilization of distilled water to make bac water ,,,,

Sterile and Water for Injection are two different things. Sterility is not enough. Sterility only means an absence active bacteria.

Water being injected must be "pyrogen free", and sterilized distilled water isn't.

I'm sure a lot of UGL and bullshit Amazon brands of BAC isn't pyrogen free, but isn't a great idea to use it.

If you have a hard time getting pharma BAC, buy "sterile water for injection" and add benzyl alcohol to make BAC.

Ateam2023

Member

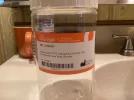

View attachment 307220would that work for homebrew bac water? With proper % of ba in a 10-50 ml vial?

Yes that's perfect

Well one can argue that If you buy distilled water and make it sterile (that doesn't mean pyrogenic free as you well said) with a .22um filter it should be probably very ok and not contain endotoxins at any dangerous level.Sterile and Water for Injection are two different things. Sterility is not enough. Sterility only means an absence active bacteria.

Water being injected must be "pyrogen free", and sterilized distilled water isn't.

I'm sure a lot of UGL and bullshit Amazon brands of BAC isn't pyrogen free, but isn't a great idea to use it.

If you have a hard time getting pharma BAC, buy "sterile water for injection" and add benzyl alcohol to make BAC.

But yes it's best to use non pyrogenic water aka sterile water for injection

Similar threads

- Replies

- 7

- Views

- 454

- Replies

- 2

- Views

- 124

- Replies

- 3

- Views

- 52