What I am about to say is from an engineering and fluid dynamics perspective. I don’t want to pretend I have any knowledge on this topic beyond that.

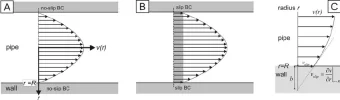

You are describing what happens on a microscopic level for flow through a pipe. Specificity the types of flow and boundary conditions at the wall. The below image is the 2D velocity profiles (velocity gradient) with 2 types of boundary conditions.

View attachment 316393

The shear stress is proportional to the velocity gradient. Think of each of those arrows as a slab of fluid moving at different speeds. There is a friction force between each layer that is one type of shear stress.

You can have different types of flow through a pipe. Laminar flow or turbulent flow. Turbulent flow will causes a lot of shear stress and energy loss. You can do quick calculations to find the reynolds number for your situation to see what type of flow you have.

But I would have to look up flow through a porous material, not sure how the filter comes into play.

All of that was to say that the velocity matters. lol

You could go to a larger needle and increase the velocity and still have the same problem. You could keep the smaller needle and decrease the velocity and maybe have better success but I would imagine the larger needle with higher velocity is preferred for manufacturing reasons.

Im not familiar with the problem, I just like this shit.